Digital ink meets electronic paper

“Digital ink meets electronic paper”, The Economist Technology Quarterly, December 7th 2000

Printed with digital ink, electronic paper promises an era of reprogrammable newspapers, books, billboards, garments and even wallpaper

WELCOME to the paperless office. Mind the pile of newspapers on the floor and ignore the stacks of books, files and magazines around the walls. Settle down in this citadel of high technology and enjoy the glorious 22-inch (56-centimetre) colour portal to the electronic world. Try to forget the fact that most serious reading is still done using a technology that is 2,000 years old.

It is no accident that, ten years into the information-technology revolution, people are still bound to paper. It has an awesome list of specifications: it is cheap, flexible, light, foldable and portable. It also offers good contrast and has high and even reflectivity, and it can be read from a wide range of angles. Put a book or magazine back on the shelf and it will still be there years later. Better still, it needs no batteries.

Although the monitor of a desktop computer can update itself with fresh information and can even show videos, its cathode-ray tube is power-hungry, fragile and hardly portable. Draw back the window blinds and the screen fades, becoming impossible to read in direct sunlight. The modern liquid-crystal screen in laptop computers, though lighter in weight, is even worse. Liquid-crystal displays are pricier than cathode-ray tubes. And, while they are easier to read in sunlight, cheap monochrome liquid-crystal displays used in calculators, mobile phones and personal digital assistants all have many of the same flaws.

Such problems have driven a two-decade search for something better. What was envisaged was some kind of “electronic paper”—a display with all the reflective qualities of paper, but one that could be updated electronically. Today, this science fantasy is becoming a reality. At least four companies are pioneering technologies for electronic paper and have prototypes in various stages of development. But their definitions of electronic paper depend largely on the imaging technology they have chosen.

What they agree on, however, is that electronic paper needs to work by reflected light, just like real paper—because that is what the human eye has evolved to deal with. Most modern displays are lit from behind, so strong light merely competes with the image. But a display based on reflected light would actually improve when taken outside. Also, electronic paper must consume no power after the text and images have been put on to it. And it needs to be comparable in weight and thickness to real paper and, ideally, to be foldable as well.

The applications for such electronic paper would be almost limitless. It could form collapsable displays for hand-held devices and laptop computers. It could be used in signs and posters. If it could be made cheap enough, it could be used for billboard advertisements or even as reprogrammable wallpaper. And if electronic paper could be made thin and flexible enough, it would be possible to make an entire book out of it—a reprogrammable paperback capable of holding a whole library.

Digitising the ink

When a coin is flipped, it lands in one of two positions—heads or tails. In short, it is bi-stable. Each of the companies trying to make electronic paper is exploring displays with bi-stable components that are either reflective or non-reflective (ie, black or white). Energy is needed to put them into either position. But once there, they remain there.

Imagine that a printed article were made of millions of incredibly tiny coins that are black on one side and white on the other. Those that form the letters would be black-side up; the rest white-side up. If all the coins were flipped to face white-side up, the text on the article would vanish. Electronic paper is based on this simple principle, with bi-stable components being controlled by applying an electric charge.

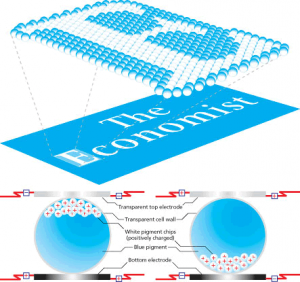

E Ink Corporation is a firm that spun out of the Media Lab at the Massachusetts Institute of Technology. The company’s name stands for electrophoretic ink, which is made up of minuscule switchable capsules of ink. Each 100-micron capsule (the thickness of a human hair) is dark blue when seen from above. But because the capsules contain positively charged particles of white pigment, these move to the top of a capsule and turn it white when a negative charge is applied. The result is a thin, flexible display, with a contrast that matches that of paper.

The company’s first product is a rigid indoor display board called “Immedia”. The electrophoretic ink has been laminated on to a layer of circuitry controlled by standard display software. With a protective sponge backing, the signs are little more than 5mm thick. Because the signs are large, the resolution needed is a very low 2-3 dpi (dots per inch). But the company claims to have produced displays with resolutions of 200 dpi. (For comparison, a computer monitor works at 70 dpi and most laser printers these days deliver 600 dpi.) Like real paper, white-on-blue Immedia displays, measuring 44 inches by 15 inches, have high contrast in daylight and a wide viewing angle. They also consume little power—a thousand would use less energy than a standard light bulb. Other two-colour options are available, and E Ink says full colour is possible.

E Ink’s displays have been tested around America in J.C. Penney department stores, Eckerd Drug Stores, on sandwich boards and by the Arizona Republic. The newspaper’s trial showed how boards could carry daily news in locations around Phoenix, Arizona, using built-in two-way pagers that were controlled via the Internet. Other communications options include the standard methods of computer networking and wiring (eg, Ethernet and RS232). Meanwhile, the company is developing an infra-red connection device, so its displays can be updated using a personal digital assistant such as a Palm Pilot. And, inevitably, there will be a Bluetooth option. “Bluetooth excites us, because multiple signs in a store could run off a single communications platform,” says Jim Iuliano, E Ink’s chief executive.

Thanks to digital ink, newspapers, books, billboards, walls and even T–shirts will become interactive, animated and even change by the hour.

Based on these trials, Mr Iuliano hopes that a retail revolution is about to occur. The company reckons that its Immedia boards are changing the way that retailers communicate with customers, allowing shops to sell more goods or to generate more traffic. E Ink estimates that the market for point-of-sale advertising in America is worth $13 billion a year, but only a quarter of that is now exploited by store-owners. Immedia displays do not have to be designed, printed, mailed and hung each time a new one is needed, but merely reprogrammed on the fly to take advantage of changing needs during the day. Convenience stores could use them to remind customers to pick up milk, cereals and orange juice early in the day, and flowers and chocolate in the evening.

At present, Immedia boards can be leased for $60-80 a month or purchased outright for $1,000. Next year, E Ink plans to make fade-resistant Immedia displays for shop windows, and hopes to produce outdoor signs and billboards. The company envisages electronic books that can show volumes of information as easy as, literally, flipping a page. After that, “permanent” newspapers that update themselves daily via wireless broadcasts would be the next logical development.

Clearly, Immedia displays, with their circuitry wired into the back, are not the be-all and end-all of electronic paper. Last June, Lucent Technologies licensed the plastic transistor technology developed at its Bell Labs research centre to E Ink in exchange for a minority stake in the fledgling company. This uses a grid of plastic transistors on top of the electrophoretic ink to create the electric fields needed to form the text and images. The “plastic” transistors are made of a material, known as “F-15”, that is composed of huge organic molecules. Like conventional semiconductors made from silicon, F-15’s long, organic molecules are excellent carriers of electrons, but they are also flexible and transparent, and can be printed on a variety of surfaces—including cloth or even paper.

This raises the possibility of being able to print the pager circuitry, along with the ink, on ordinary paper. If pages of this paper were then bound as a book, a microprocessor, memory chip and battery could be stored in the spine. This would allow hundreds, even thousands, of books to be stored in a single volume that actually looked and felt like a real book. Experts reckon that such a digital book is only five years away.

Paper chase

The history of electronic paper goes back more than 20 years to an invention by Nick Sheridon of Xerox’s Palo Alto Research Centre (PARC) in California. Called Gyricon, the concept is based on a transparent sandwich of millions of charged “bi-chromal” beads, each measuring no more than 50-100 microns in diameter. The whole sandwich is no thicker than five sheets of ordinary paper. The bi-chromal beads have one white hemisphere and one black, each hemisphere carrying an opposing electrical charge. The beads—typically around 20m of them to a standard page—all sit in an oil-filled cavity. When a charge is applied to the surface of the sheet, the beads rotate (to reveal the relevant colour) and move to the top of the cavity. There they remain, because they have a similar density to the oil.

- The medium is the message

The result is a flexible display with a relatively low contrast ratio of six to one. PARC has already produced a long rubber sheet of it that can be cut to size. With the 50-micron beads used today, PARC’s electronic paper has a resolution of 200 dpi. By moving to 30-micron beads, the resolution will increase to 300 dpi. This is a little better than newsprint, and Gyricon can also supply several shades of grey. The difficult part, however, is imprinting text and images on to such a page. One early suggestion was to feed a Gyricon sheet through a printer-like device that transferred the appropriate pattern of electric charges to the page. But this would have been little more than a photocopier with re-usable paper—an idea that had been tried before and had failed.

Instead, Xerox is expected to pursue the idea of printing on Gyricon with a “magic wand”—a tool covered with an array of electric contacts and memory devices. Drawing the wand over the “paper”, or pulling it through a slot in the wand, transfers the desired charge pattern, and hence the words and images. One attraction of the wand-and-paper approach is that it could become a portable printer, copier, fax and scanner. That would broaden Gyricon’s appeal, though not for busy commuters reading a 48-page electronic newspaper while strap-hanging their way to work.

If Gyricon is to succeed in the marketplace, it will need to find some way of imprinting the paper direct—as E Ink is doing. Mr Sheridon, who believes that the “linear electrode array” (ie, wand) is the simplest way of transferring images to electronic paper, agrees that self-imprinting paper with a plastic transistor is probably the ultimate solution—but ten years away.

With all its recent troubles, Xerox has been quiet about Gyricon developments. In June 1999, the company announced that 3M, in Minneapolis, was to develop the electronic paper, although neither company gave any hint of when it might be in mass production. Nor did Xerox show Gyricon at the annual International Display Research Conference in September. Sceptics point out that Xerox has a history of failing to commercialise great ideas developed inside PARC—from Ethernet to the computer mouse, drop-down menus and the graphical user-interface popularised by Apple’s Macintosh and Microsoft’s Windows. Gyricon could end up going the same way.

The most popular display technology today is liquid crystal—found in everything from digital watches and calculators to mobile phones, flat-screen televisions and even microwave ovens. The liquid-crystal display (LCD) relies on molecules with optical properties that change from transparent to opaque when a charge is applied to them. Despite the promise of digital ink and electronic paper, LCDs are hardly being threatened. Indeed, two companies—Kent Displays of Kent, Ohio, and Hewlett-Packard of Palo Alto—are working on LCDs that are as bi-stable and reflective as electronic paper.

While cagey about its technology, Hewlett-Packard is known to be exploring the use of slightly elastic liquid-crystal materials made up of molecules that can be stable in two different orientations, and so will not need energy to maintain the display. Meanwhile, Kent Displays is working on “cholesteric” liquid crystals—so-called because the liquid-crystal material is made from cholesterol. The cholesteric-LCD is chemically altered so that it is bi-stable, being reflective or non-reflective depending on the direction of the electric current applied to its surface.

Ingeniously, Kent makes three versions of the display, which can reflect red, blue or green light—the primary colours from which all others are composed. By stacking the three versions as a sandwich, the company can produce a highly reflective 4,000-colour display with a contrast ratio as good as ink on paper. Because it works by reflected light, its contrast ratio (normally 20 to 1) gets even better when taken out into the sunlight. As it can be switched from reflective to non-reflective in a brisk 30 milliseconds, Kent’s colour display can also show videos. In addition, because the cholesteric-LCD does not work until the electric current applied to it reaches a certain threshold, there is little “cross-talk” between neighbouring elements in the display. As a result, a much simpler and cheaper form of wiring can be used to imprint the individual picture elements in the display and switch them on and off. In production, a six-inch display costs $300.

Kent has not stopped at full colour. The company has created a prototype electronic book with Honeywell and the Pentagon’s Defence Advanced Research Projects Agency. By adding a fourth layer capable of reflecting infra-red radiation to the sandwich, the electronic book can be read in the dark with night-vision goggles. Anything emissive, such as a backlit laptop display, would be too bright and too easily detected by enemy surveillance in the battlefield at night. But can a cholesteric display be considered electronic paper? Though only 1.5mm thick, it still needs a rigid plastic surface. That means it cannot be folded or even furled. These are mere catch-phrases, says Mr Miceli. “What we are talking about here is a technology that allows images to be displayed that do not require power.”

Writing on the wall

Although getting better all the time, display technology—and the related constraint of battery life—has been a limiting factor in the development of portable consumer electronics. That is because existing displays have to be refreshed continuously. Researchers reckon that, all things being equal, bi-stable displays consume less than a hundredth of the power used in refreshed displays. That could translate into either much smaller batteries or a much longer period between charges.

Kent may be the first to deliver a consumer display, but E Ink has a highly visible product in the marketplace and seems to be beating a steady path to the ultimate goal of producing a real digital alternative to the book, magazine or newspaper. On price, Xerox could still succeed with Gyricon. As an alternative to newsprint, Kent’s cholesteric display is not in the running, while E Ink’s product is estimated to cost $10 a article and Xerox’s only $20 a square metre. But Kent questions whether its rivals really can produce their display materials plus their drive mechanisms for those kinds of prices.

With so many different applications, however, the $30 billion market for electronic displays would seem big enough for all. One thing is certain: the dramatic decline in cost and power-consumption of electronic displays is going to transform the way they are used. Newspapers, books, posters, walls and even T-shirts will no longer be passive objects with fixed messages printed on them. They will become interactive, animated and even change by the hour.